Developing Forward-Thinking Technologies

Engine Technology ▸

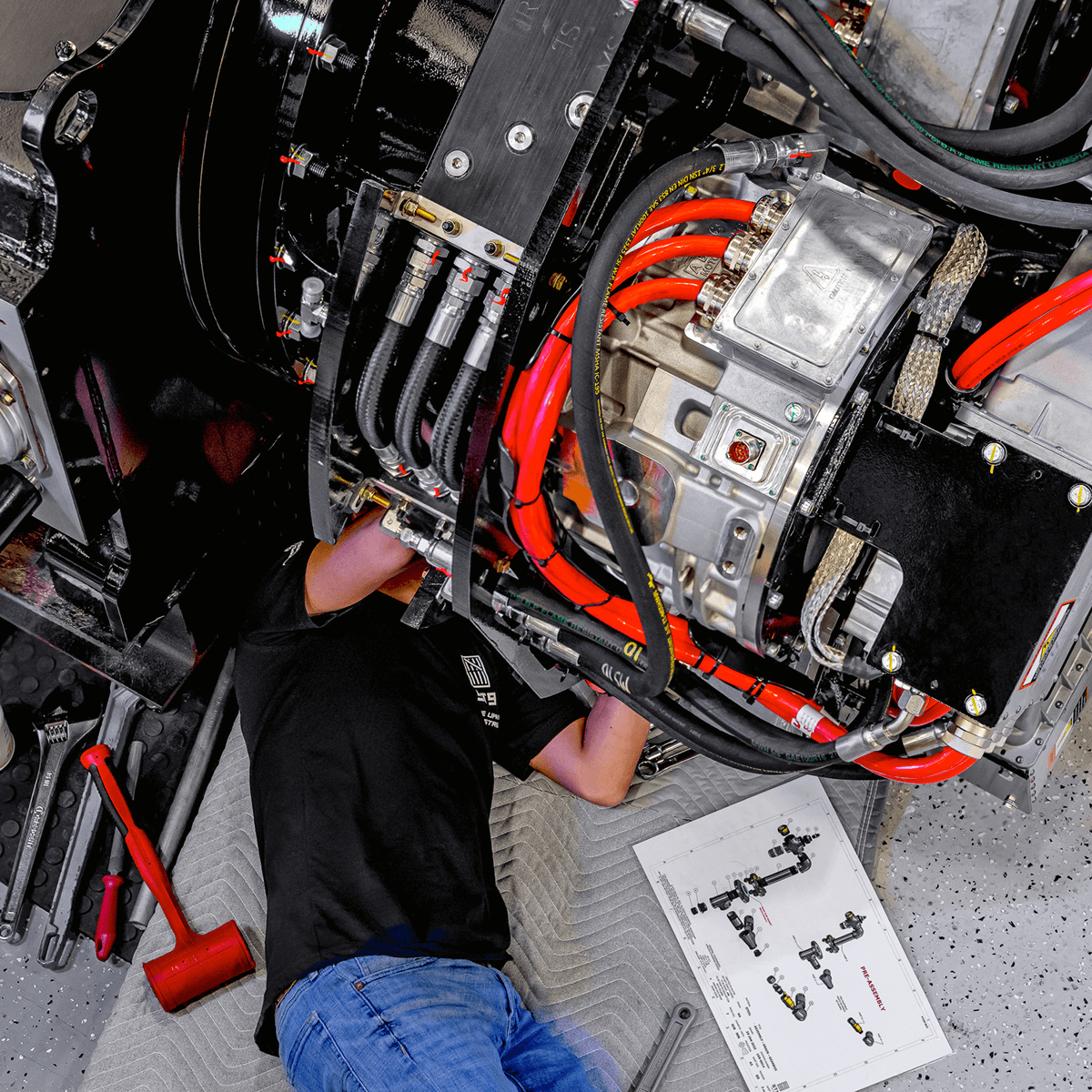

Reduction of emissions on location is accomplished via the deployment of next-generation frac engine technology. Liberty has been an enthusiastic test partner and early adopter of each improved engine technology, with the latest being Tier IV DGB (Dynamic Gas Blending). The latest step is our digiTechnologies electric and natural-gas-powered frac fleets that we have been developing over the last three years.

Digital Optimization Tools ▸

Liberty has developed a comprehensive suite of digital optimization tools that create unprecedented efficiency gains. Our extensive database of shale wells lays the groundwork knowledge for our physics-constrained multivariate analysis “Big Data” tools. Coupled with our direct measurement diagnostics of fracture growth, we ensure each shale well consumes fewer resources and has lower emissions while boasting higher productivity.

In 2014 Liberty moved the transport of sand to a completely containerized method. The innovation of containerized sand removed the pneumatic trailer from the equation, eliminating the noise and dust and optimizing the volumes of sand that could be transported. It also led to as much as a 10-fold reduction in silica exposure, providing a much safer environment for personnel on location.

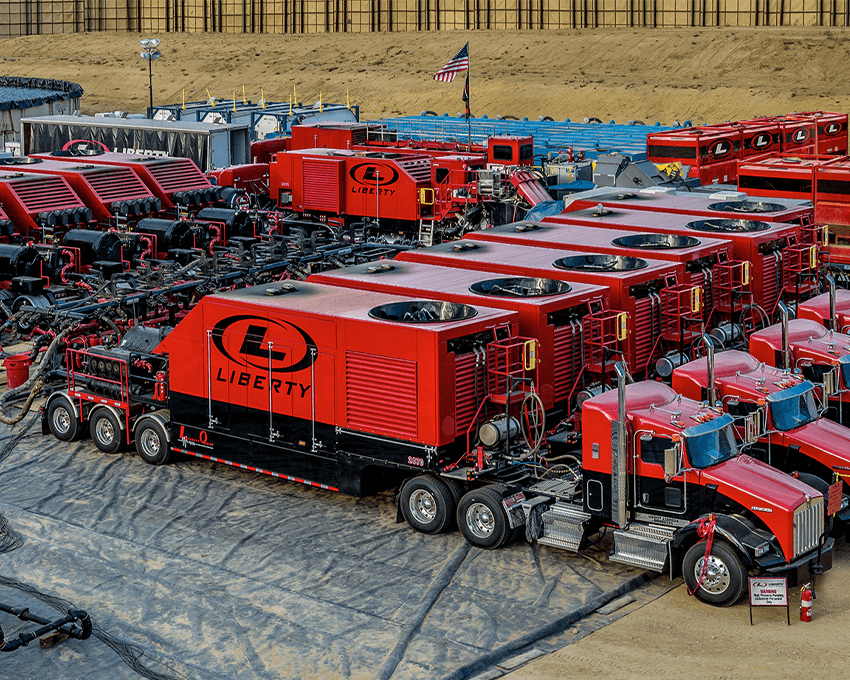

QuietFleet ▸

The Quiet Fleet represents a huge step forward in fracturing equipment. Noise levels are reduced by approximately 3X when compared to a conventional fleet. At 500 feet away, the equipment cannot be heard above ordinary conversation making us better neighbors.