Next-Gen Electric and Hybrid Completions Technology

digiTechnologies ▸

A Modular System

Powering an electric grid requires two key components, consistent baseload power and a highly responsive means of addressing the variations in demand over the course of a day. Pumping a frac treatment is no different. Our digiTechnologies suite is specifically designed to work together to meet this need.

digiPrime

The workhorse, digiPrime is engineered to provide steady baseload pumping horsepower.

digiFrac

digiFrac provides the finesse that allows for the fine-tuning of rate and pressure as the job progresses.

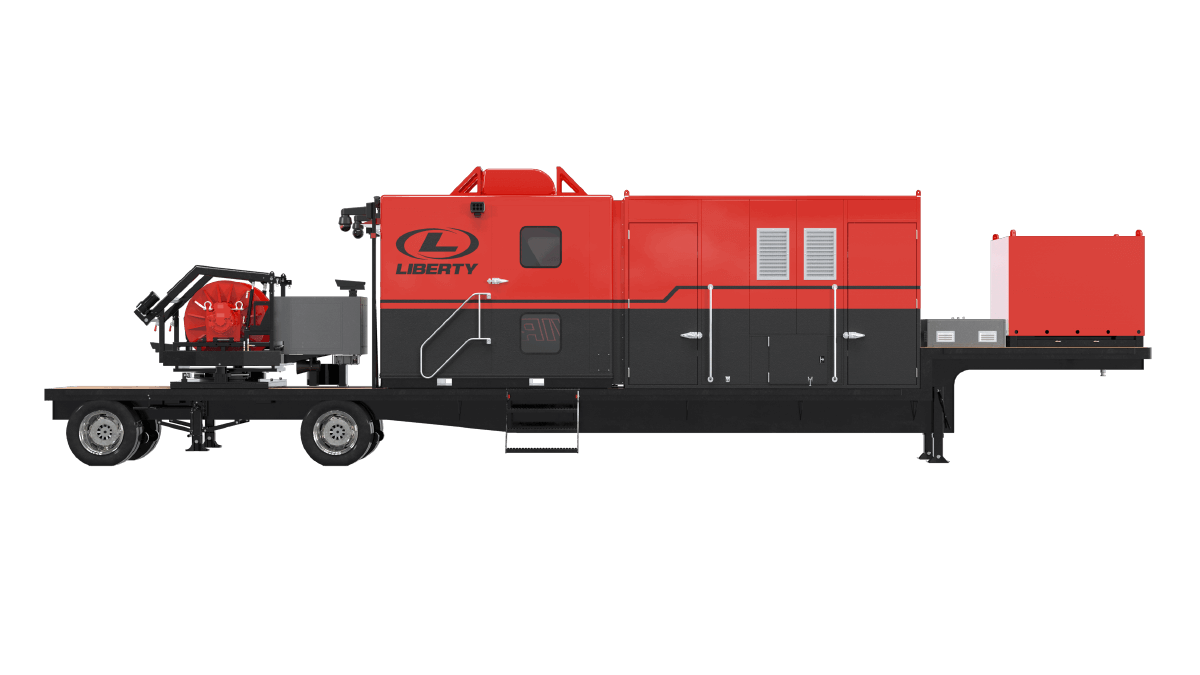

digiPrime ▸

Hybrid Frac System

The industry’s first natural gas hybrid frac system, digiPrime offers even lower emissions with the MTU 16V4000 engine’s 45% thermal efficiency and higher power density in a reduced footprint design. The new Prime pumps include Liberty’s Quiet Fleet technology and boast a fully electric auxiliary system including a generator motor for engine pre-load, an electric fan, electric pumps, and electric start using onboard batteries.

digiPrime’s hybrid pump design provides the power generation capability to electrify the entire site, including the blender, wireline, and proppant handling equipment. The 100KW integrated battery system and generator motor together enables engine pre-load and power generation, cooling fan, lubrication pumps, and auto-start.

digiPrime Features

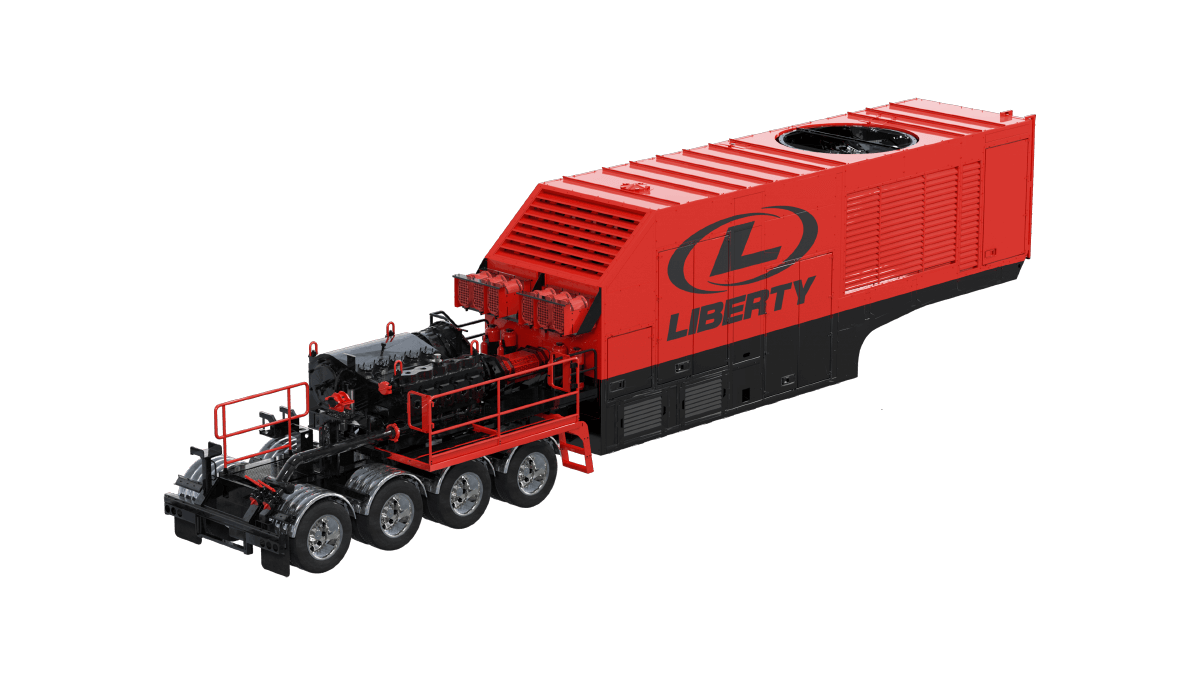

digiFrac ▸

Fully Electric Frac System

digiFrac is the industry’s first purpose-built, fully electric frac system. With an extraordinary culmination of industry insight and innovative vision, digiFrac brings more power, control, and performance to your frac site. The power-agnostic electric pump is built to run on any combination of grid and onsite natural gas generators.

An electric pump run by individual 400 HHP electric power motors powers a first-in-its-class Septaplex fluid end. The Septaplex fluid end allows for pumping at higher rates with reduced component wear, while the ten electric motors provide redundancies both on-unit and within the supply chain.

digiFrac Features

digiPower ▸

Power Management & Distribution

Powering the digiFrac pump is Rolls Royce’s 20V4000 natural gas generator set. This 100% natural gas solution provides extremely high thermal efficiencies (43%) while minimizing negative impacts on thermal efficiency due to environmental conditions. This results in the lowest emissions, and lowest fuel consumption engine on the market.

In some cases, a grid connection may be available on location to provide some of the necessary electrical power for the frac equipment. digiPower’s modular platform allows the system to accommodate any amount of grid input, from a few megawatts to enough power to run the whole location, all managed through our common bus distribution trailer.

digiPower Features

digiWire ▸

Electric Pumpdown Perforating

Designed to be an integral part of our digiTechnologies, the digiWire electric wireline unit is fully compatible with both digiFrac and digiPrime pumps. These units provide ESG benefits with improved reliability and emissions reduction. With precise electronics control, digiWire paves the way for automating the pump down operations.

digiWire Features